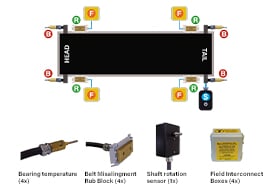

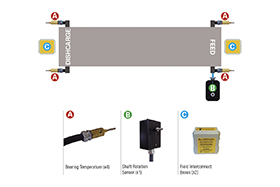

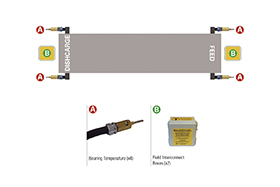

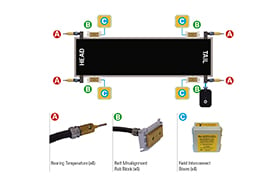

All kits come with the correct number of intrinsically safe sensors and mounting hardware required for a quick, safe, and consistent installation site after site. Everything is included in the box and there are no loose parts thus minimizing the opportunity for lost or misplaced parts on a job site. HazMon-In-A-Box kits make it simple to order, store, and install CMC’s intrinsically safe systems.

Features and Benefits

- Lower costs: Reduces cost and speeds up installation time

- No missing parts: Minimizes delays due to incorrect or missing parts

- Easy to order: Simplifies ordering and storage of parts

- Consistent: Efficient and consistent installations site after site with the right parts

- Hassle- free: All the parts you need for a hassle-free installation

Why choose AGI CMC:

AGI CMC’s hazard monitoring systems are designed to enhance grain elevator safety by providing real-time feedback from a network of sensors installed on a range of machinery such as belt conveyors, bucket elevators, drag conveyors, fans, blowers, and more. This feedback enables operators to be proactive with maintenance and repairs and goes a long way towards reducing potential dust explosion hazards and making grain elevators, feed mills, and flour milling operations safer and more productive.

Offering the highest possible safety for your workers is paramount to running your business. Unfortunately, statistics have shown that even with the best human training severe injuries and loss of life can happen. Sometimes the cause is human error but often it’s due to a mitigating factor that was never foreseen because it was beyond human notice.

AGI CMC’s monitoring system for hazardous or explosive atmosphere workplaces provides a complete monitoring solution for work environments where there is a presence of: explosive gases, vapors or liquids, combustible dusts, ignitable fibers and filings.

A series of sensors will constantly be on guard to detect the potential for danger. Workers will be able to extend their awareness well past the human limit to ensure that they are protected from the dangers that they can’t see, smell or sense or that might arise from other factors.

It is intrinsically safe for Class I, Group C & D, Divisions 1 & 2 and Class II, Group E, F & G, Divisions 1 & 2 and is specifically designed for the harsh environments found in grain processing. Included are Human Machine Interfaces (HMIs), a complete system of field wiring devices and the monitoring system’s network of sensors.