The AGI grain dryer utilizes a mixed flow design which has enabled it to be one of the most efficient dryers on the market. The dryer’s screenless operation and computerized moisture control deliver consistently higher quality grain and heavier test weights per bushel, translating into maximum return on investment.

Each dryer section is factory tested and thoroughly inspected before shipping. We also provide hands-on technical service dryer training to our dealers to ensure you get the most out of your AGI dryer.

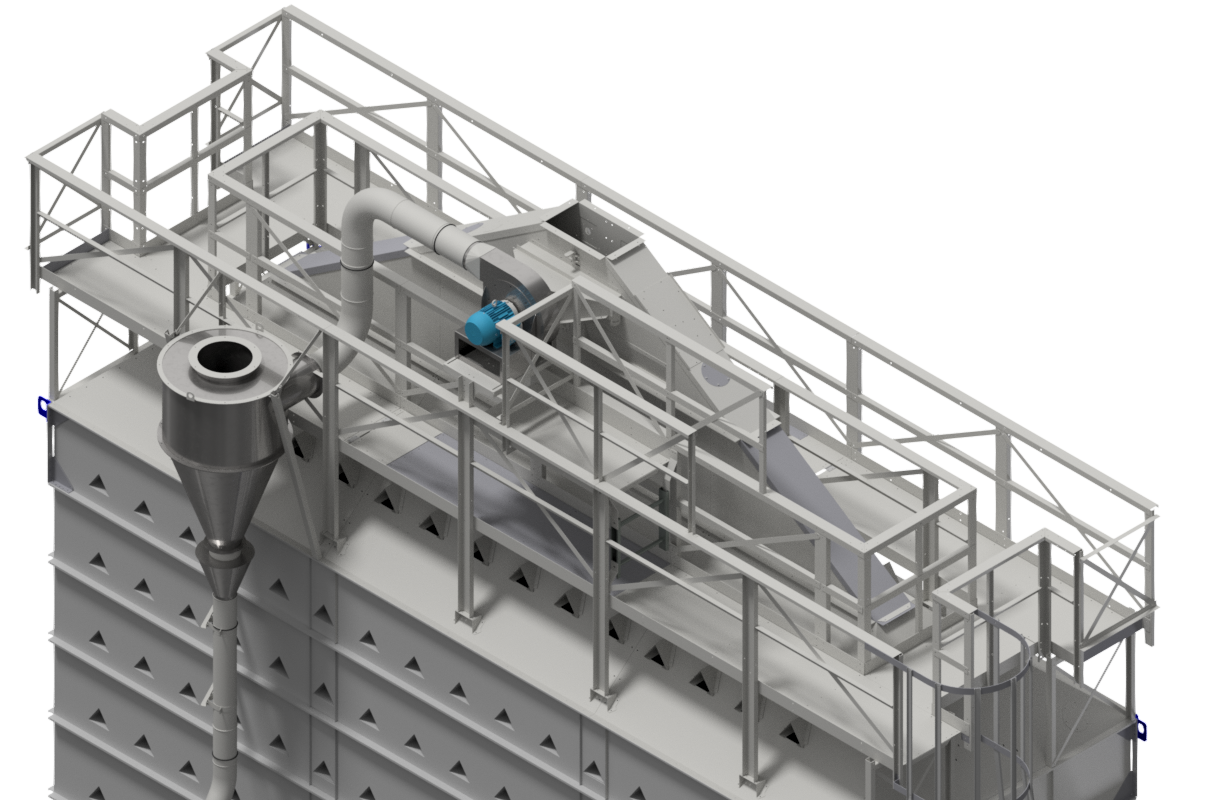

This optional integrated, patent pending, pre-cleaner system removes unwanted debris such as beeswings, fines, and chaff from grain before it enters the dryer, helping yield higher quality results.

The design of the pre-cleaner system does not require upgrades to existing filling equipment, does not increase overall dryer height and there are no screens to clean.

The optional integrated exhaust containment shroud keeps bin yards clean by minimizing airborne particulate emissions. It also prevents weather from affecting the drying process such as wind driven rain or snow.

Internal maintenance walkways for cleaning and inspection are included.