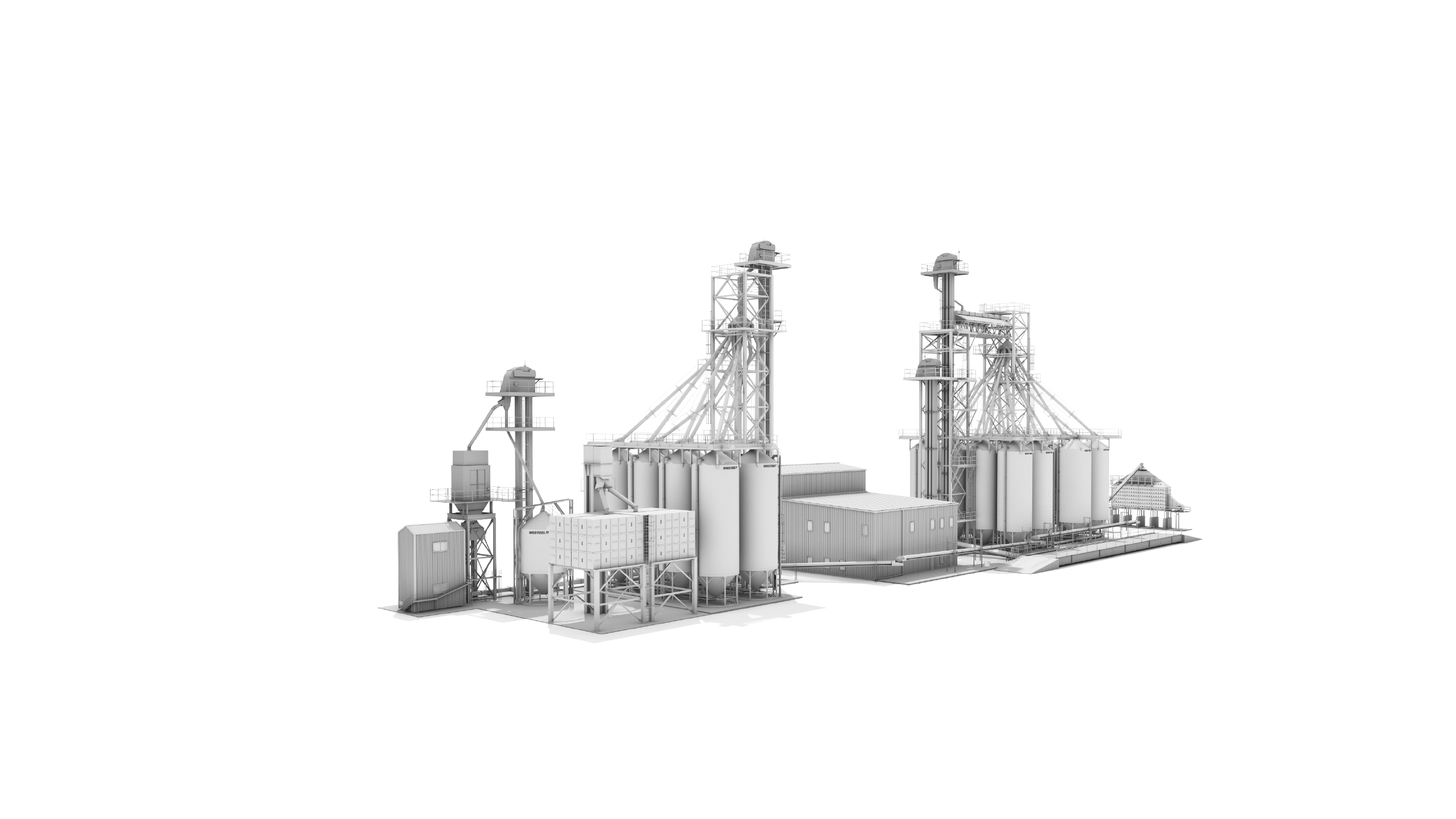

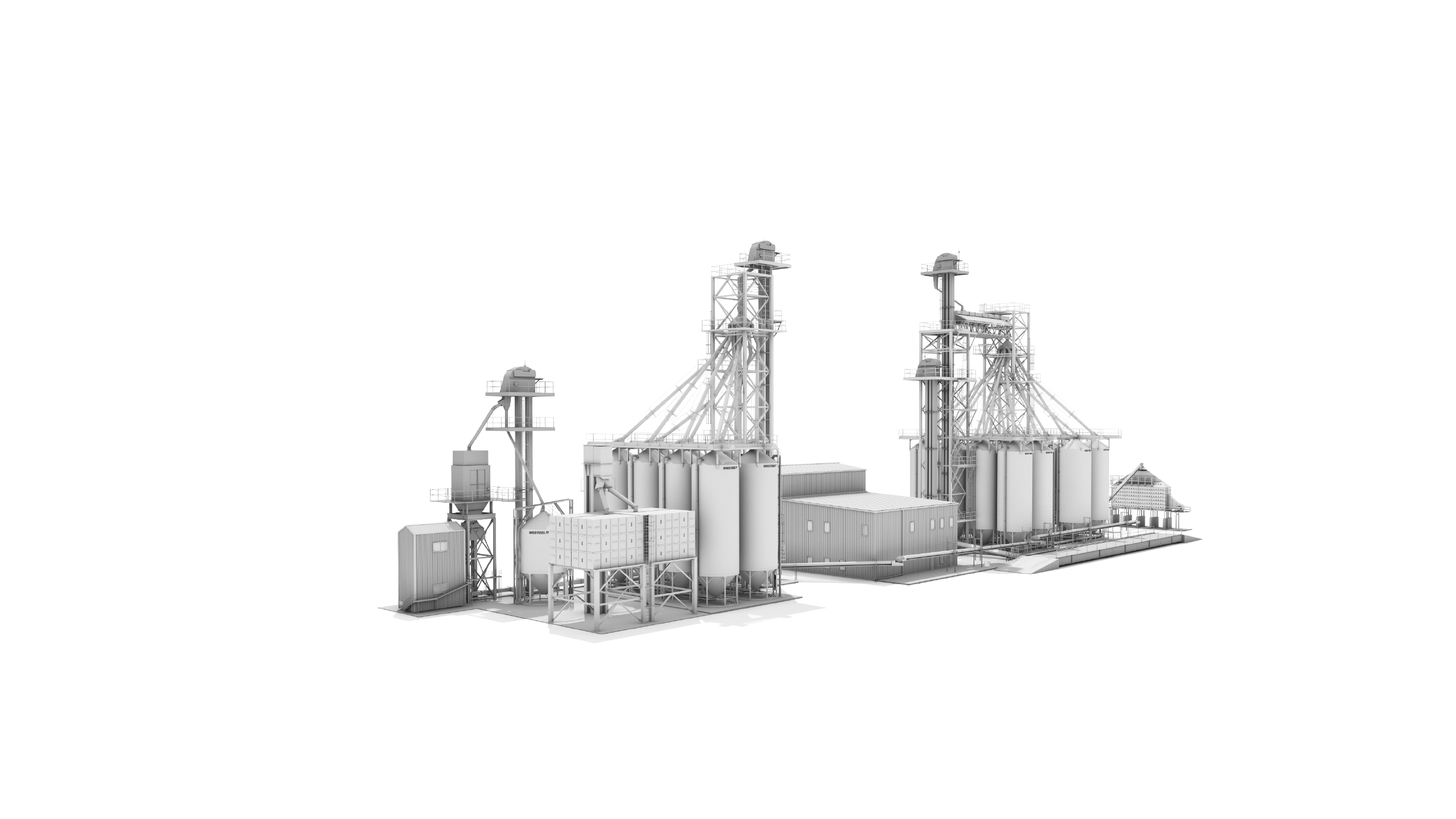

Custom equipment and solutions for handling, conveyance, storage, treatment, and processing of seed, from planning to design to installation.

VIS Distributors allow for configurations of 4 to 24 outlet spouts. Premium efficiency motors, high-quality position switches, and heavy-duty, mild-steel construction assure superior durability.

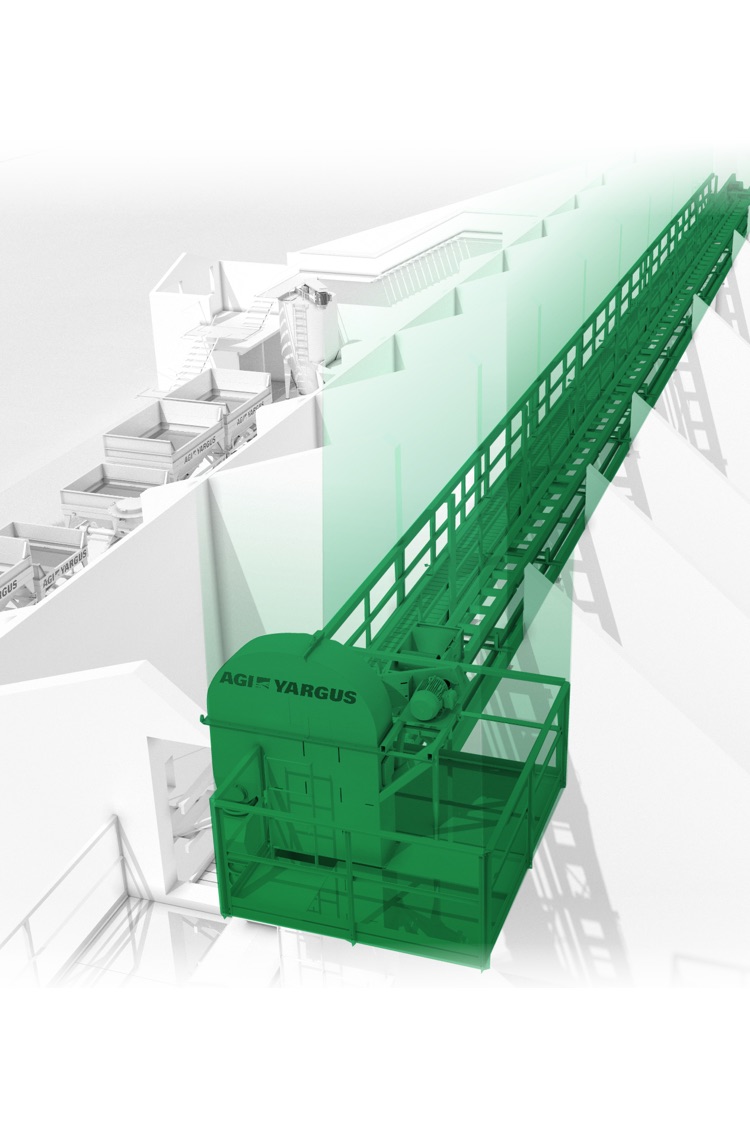

Batco underbin, jump-and-bagger/spitter conveyor combos, custom-built to suit the site geography and individual needs.

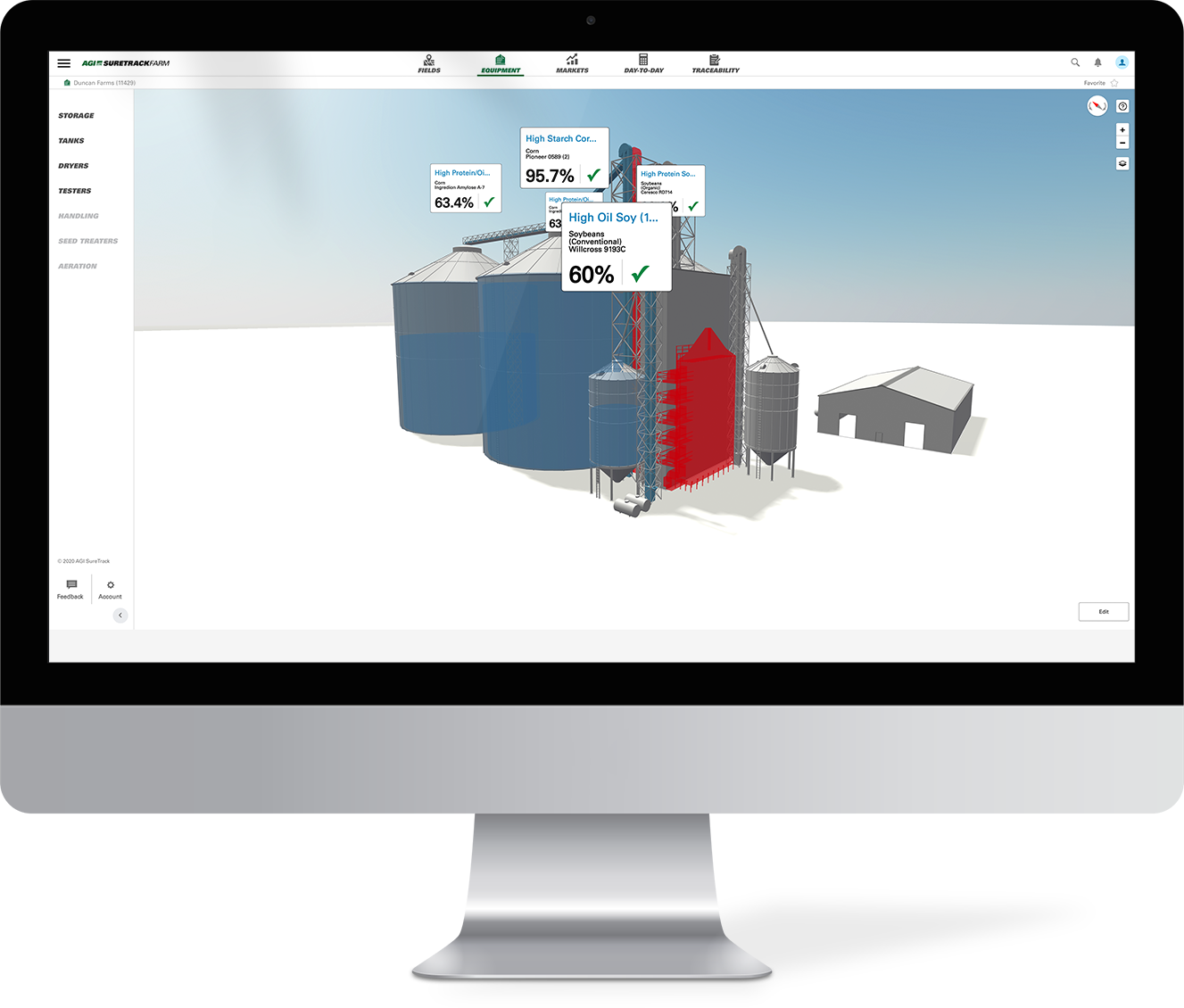

Westeel Smoothwall Bins are designed for optimal strength and provide trouble free clean-out and superior corrosion protection. These versatile bins are perfect for grain, seed, and feed.

NECO's screenless construction means no clean up or plugging, so airflow is maintained throughout drying season. Up to 20% more fuel efficient than conventional screen dryers, and heavy-gauge, G90 galvanized material for longevity.

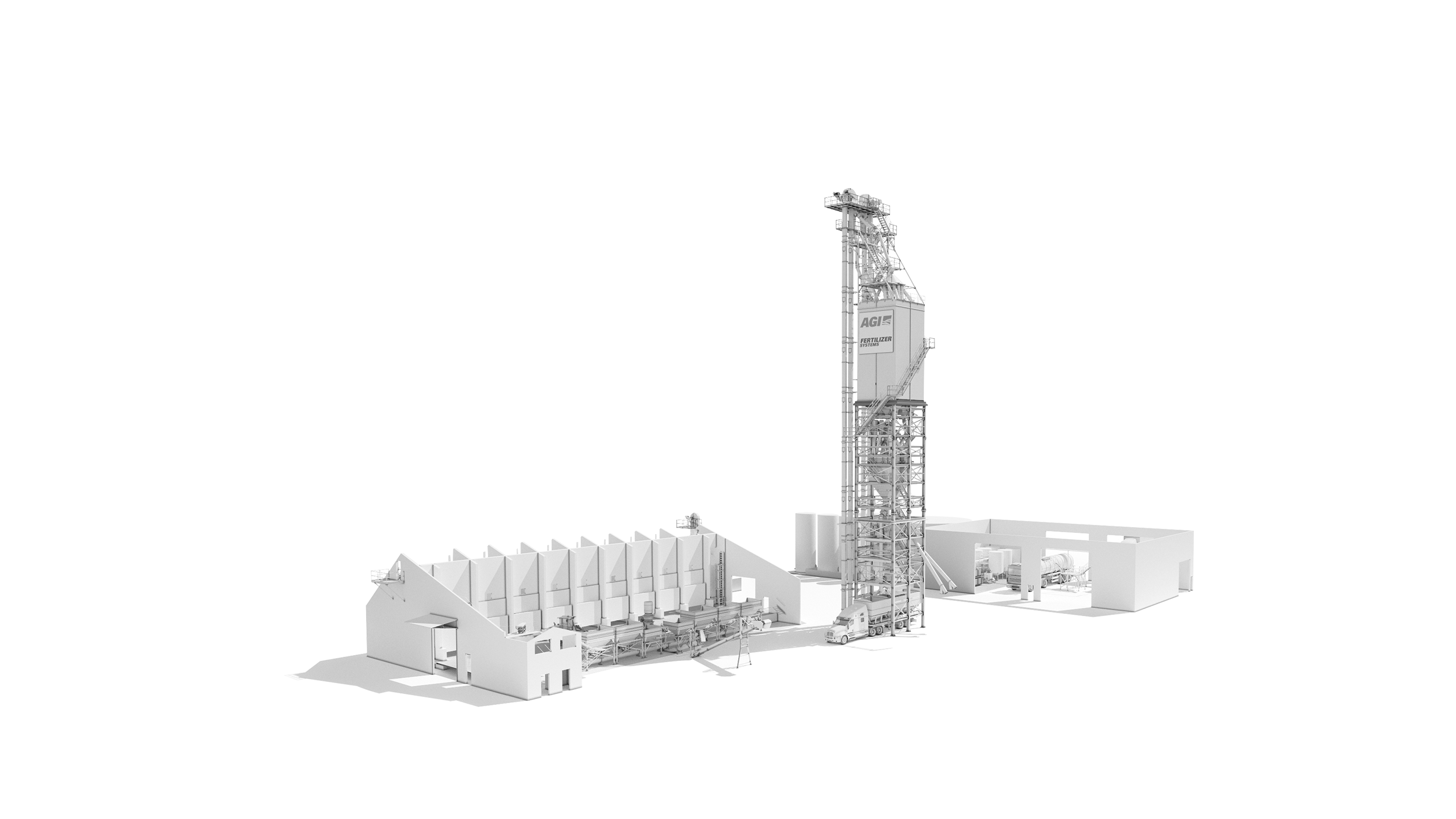

Equipment and solutions for bulk fertilizer and industrial material handling, from engineering and design to manufacturing and installation.

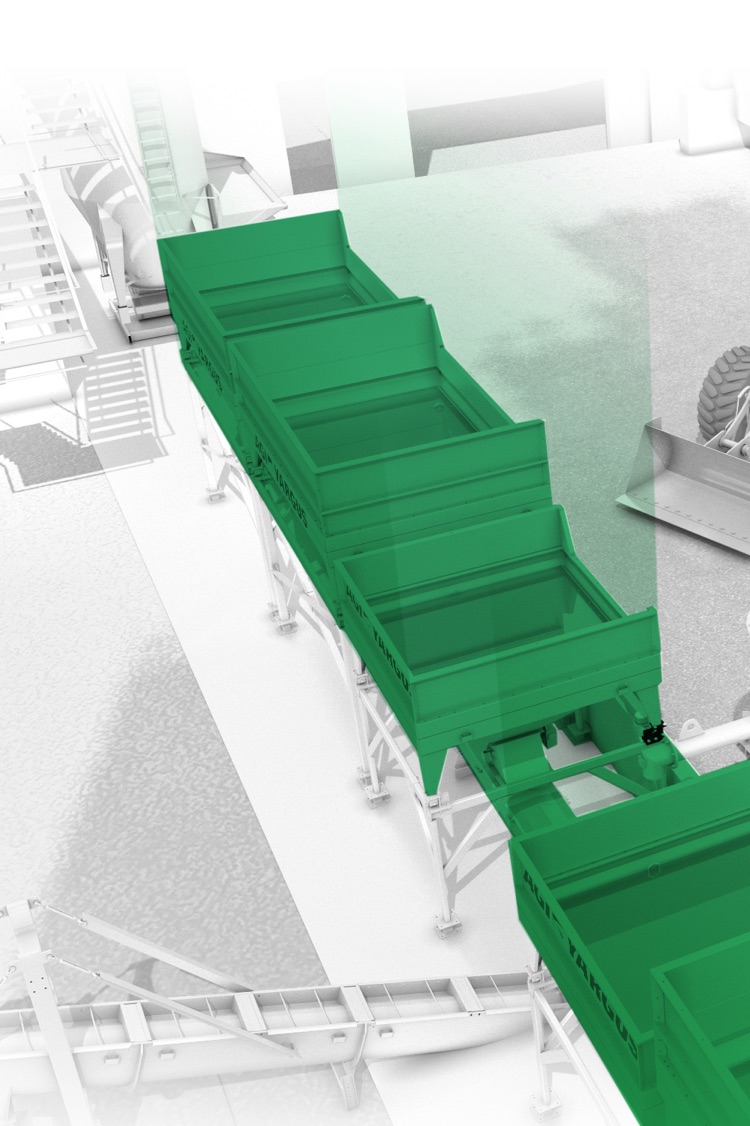

Receiving systems built for durability, strength and ease of maintenance. Designed to make your buildings more efficient.

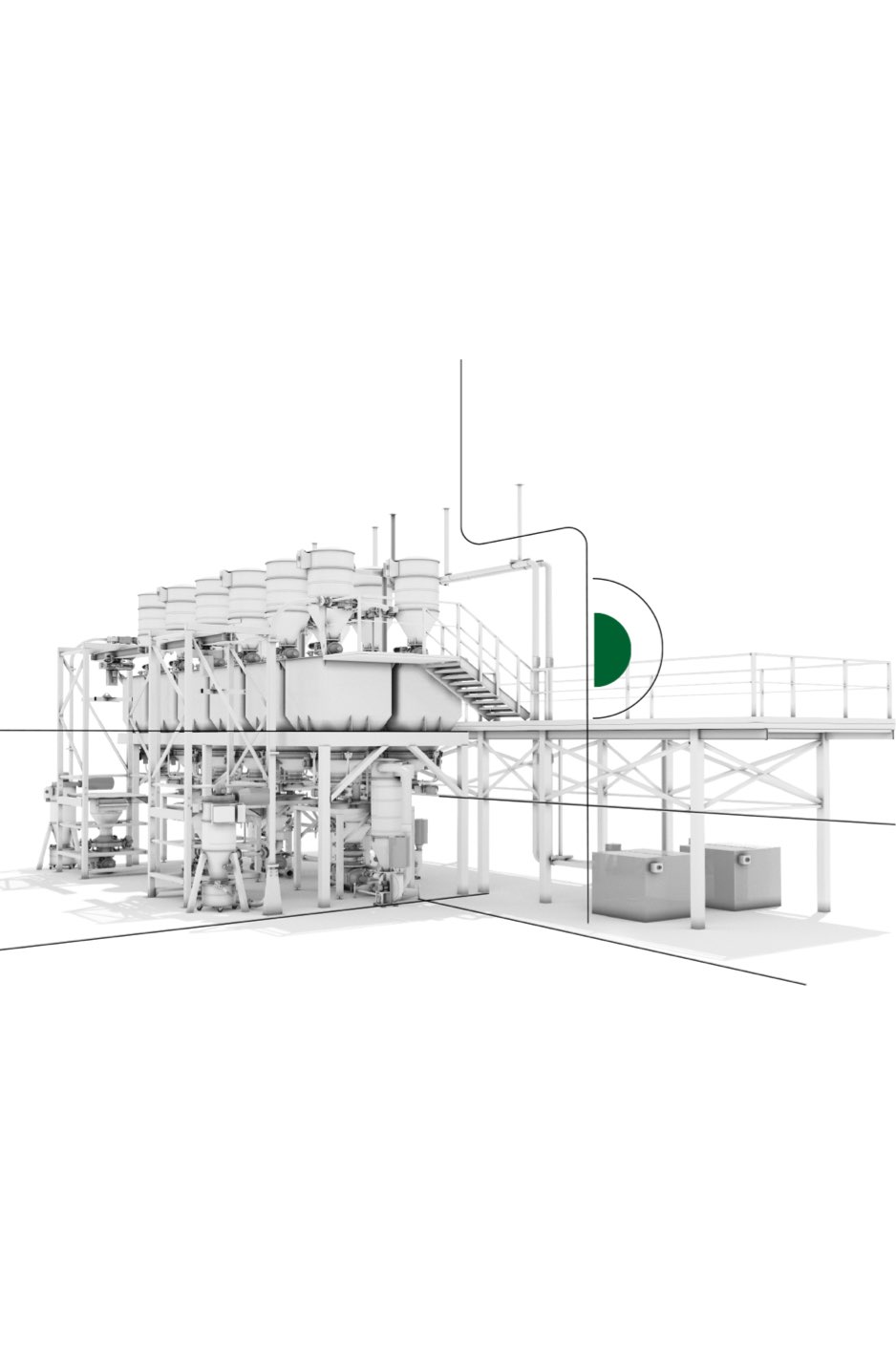

AGI Fertilizer Systems Automation software and iPad integration allows a single operator to run an entire blending plant from a wireless network.

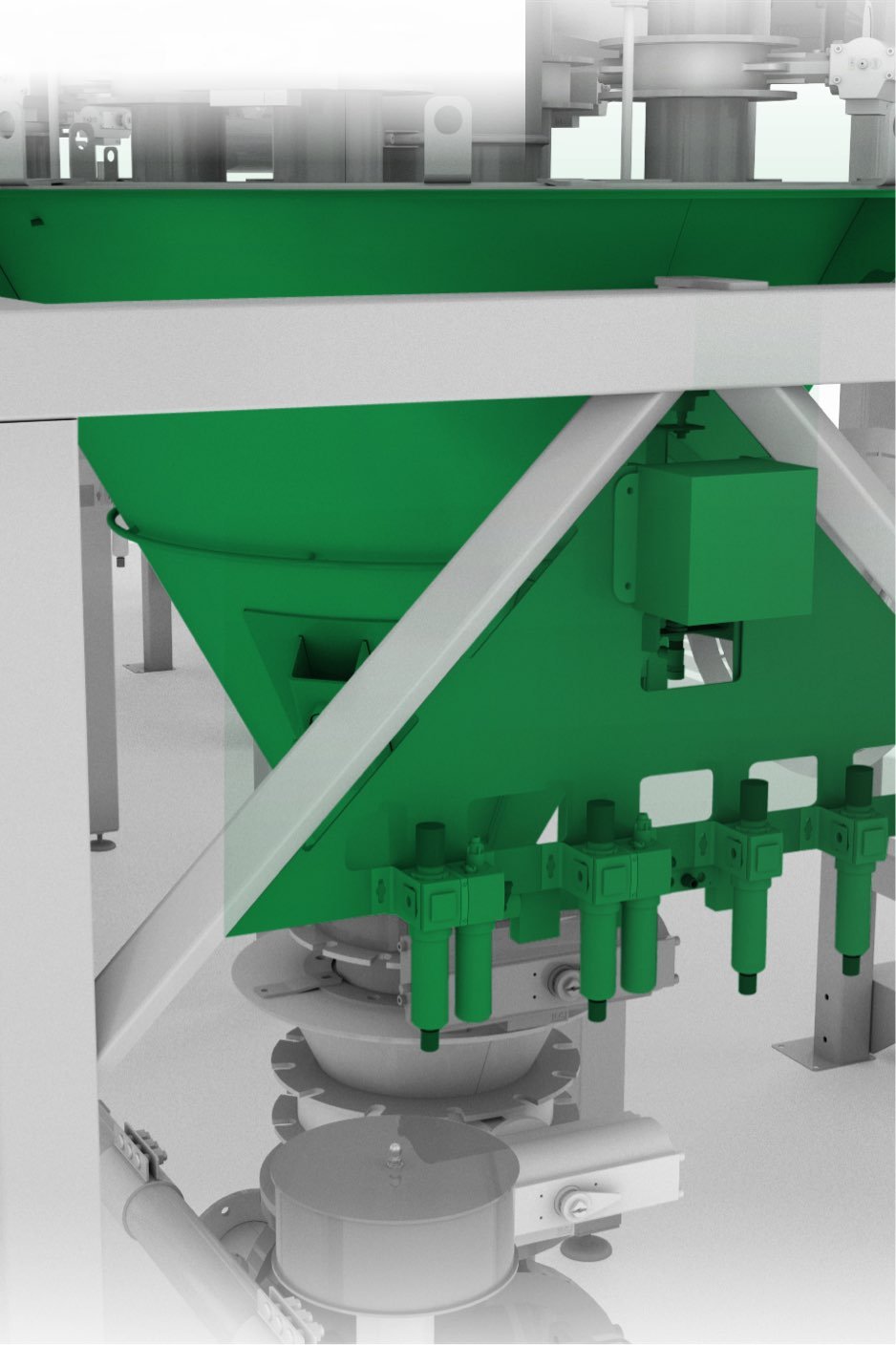

Declining weight blending system provides extremely accurate blends at efficient rates. Able to monitor and control inventory in real time.

Durable Tapered Vertical Blender and Rotary Drum Blend System allow additional batch blending options.

Four-to-six legged towers with up to 400-ton capacity at a blend rate of 250 TPH.

Load-out conveyors with power brush, return pans, and enclosed drive (belt guard) are designed to eliminate spillage, dust, and carry-back for environmentally-safe loading of fertilizer.

Fully-automated, precise weigh system for measuring up to 250 gallon batches to be injected into liquid fertilizer load-outs, metered through the most accurate metering system around.

Fully-automated plant operation with PC-driven controls. Unique free-fall adjustments ensures increasing accuracy with every load. Junge automation inspires confidence in plant operators and drivers.

Pallet scale weighing system allows for Minibulk (Shuttle) load-out for transit to other locations.

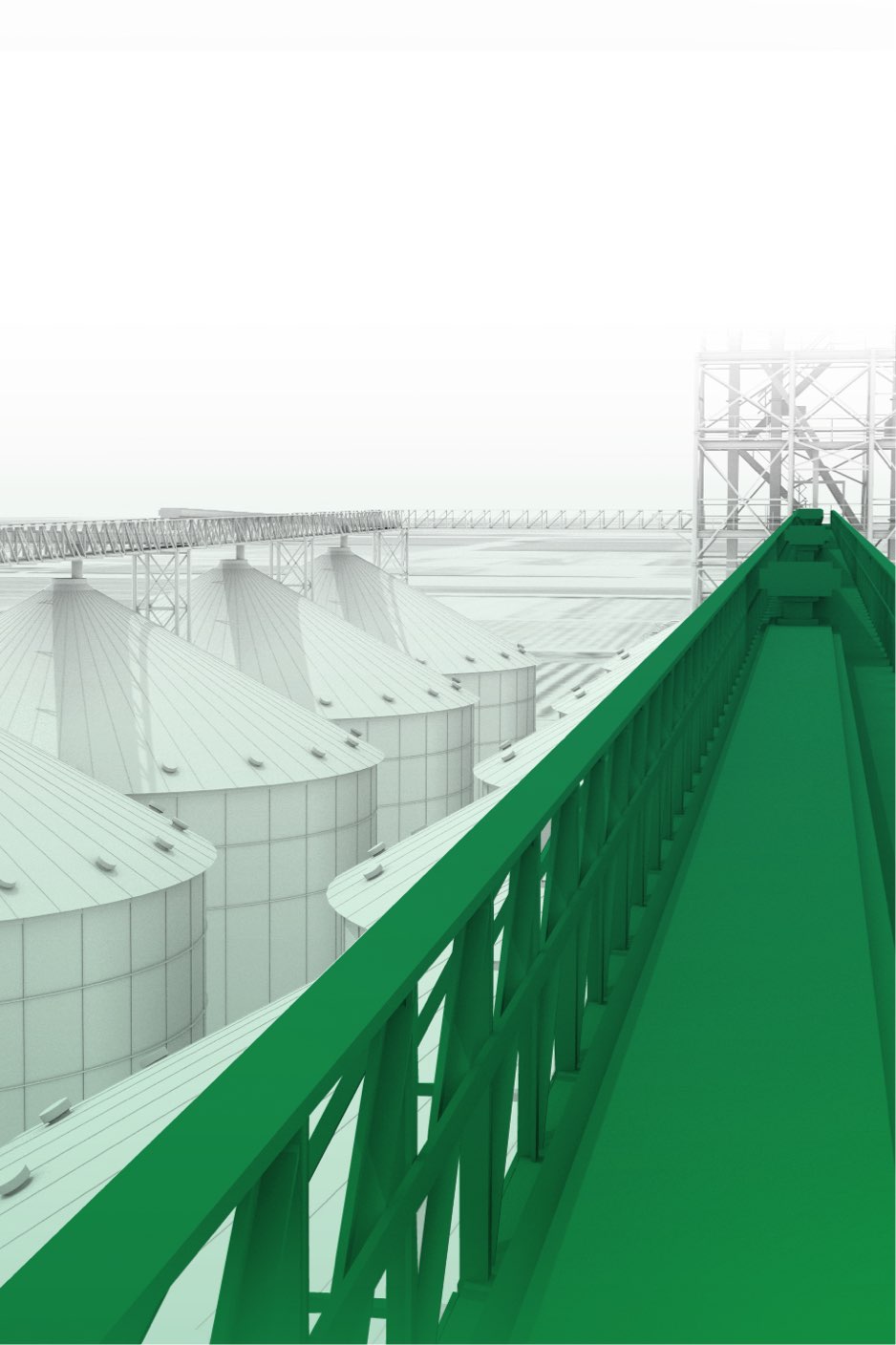

Design, manufacturing, and installation of handling and storage components and solutions for both farm and commercial needs.

Mixed flow reduces overall temperature requirements and attendant grain damage. Modular and flexible for compact shipping and sizing options.

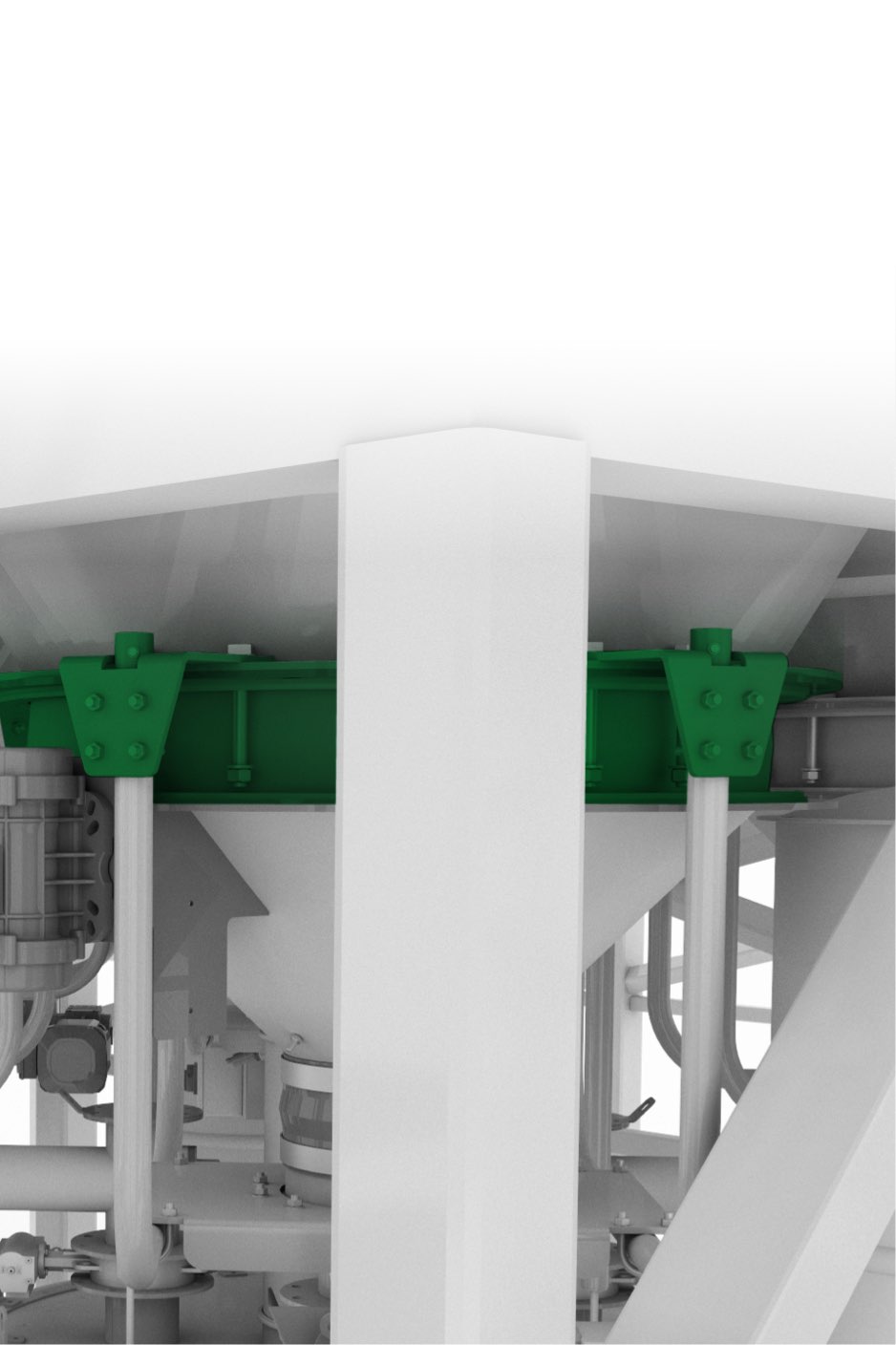

Hopper bottom storage bins are available in sizes up to 48' diameter, and the entire product line is available with seismic ratings.

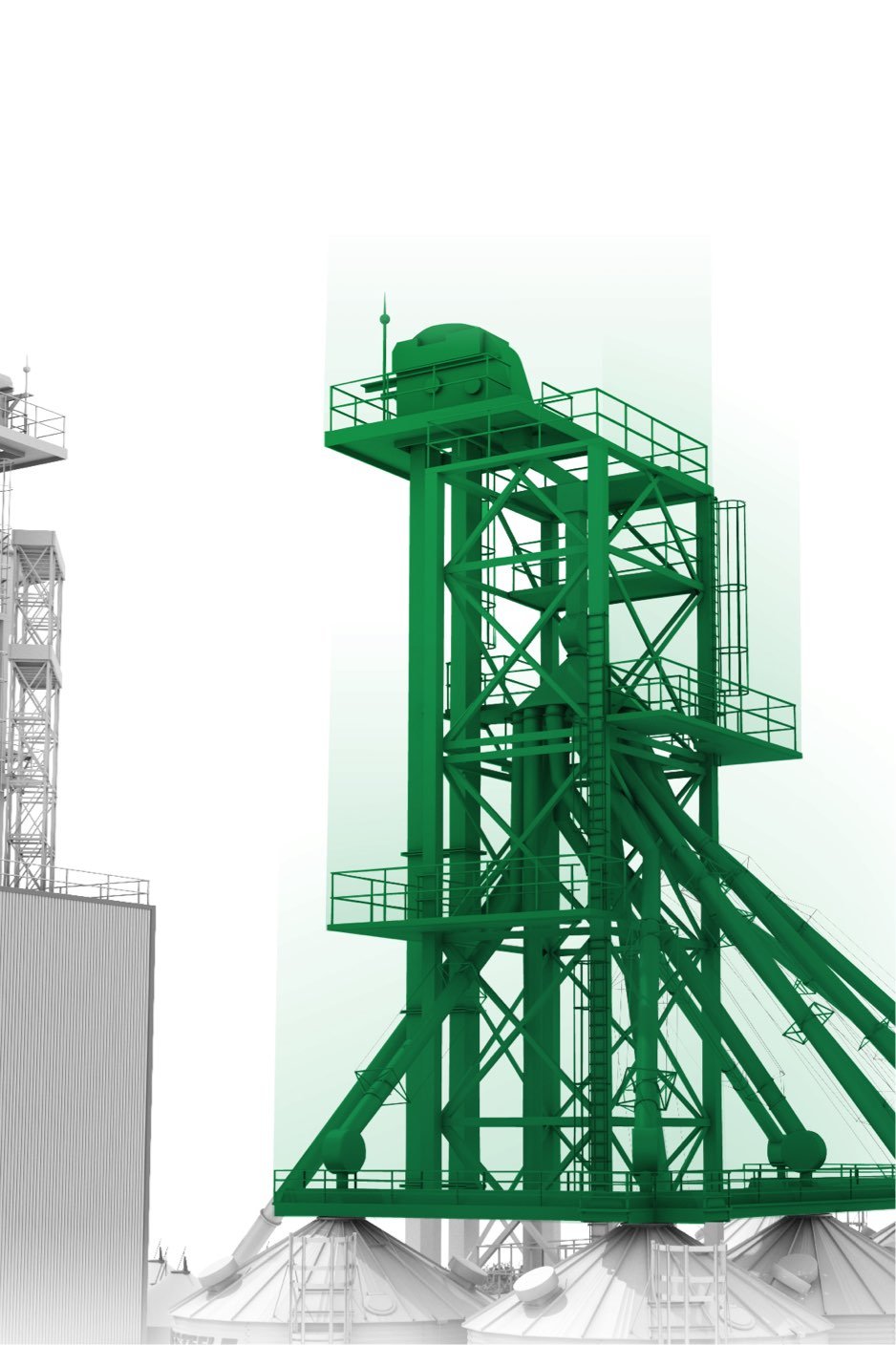

Fully custom-designed tower solutions to suit your conveying system requirements. Full-width platforms, access to all equipment, stairs as opposed to ladders, and designed in accordance with AISC 2011 and ASCE10 in addition to the IBC.

Fully-galvanized, roll-formed steel construction, ceramic-lined head shrouds, integrated bucket catchers, multiple drive options. Each elevator is custom-engineered for a specific application.

Extremely rigid, 1"-thick structural base plate permits the use of high-strength anchor bolts. Compliant with the latest IBC codes, minimum roof strength is 40 pounds per square foot and 10 kip peak load.

Handrail truss is very easy to assemble in-field. It arrives knocked down to economize on shipping. Assembly requires minimal experience and no welding.

Bins, feeders, distributors, conveyors and more, plus solutions for all your feed handling needs from field to feed bunk.

The 1632 Westeel Smoothwall Bin is capable of holding up to 6,115 bushels. State-of-the-art finish protects from weather and corrosion.Holds up to 144 tons of feed.

Westeel 2713H40 Stiffened Hopper Bin carries 24,571 bushels or 666 metric tonnes. New cone design eliminates hang-up, rot, and infestation.

Bins are specially-engineered to support catwalk and conveyor loads. 2' and 4' walkways available.

VIS Bucket Elevator and spouting allow for variable storage configurations. Capacities up to 75,000 BPH (93,750 CFH).

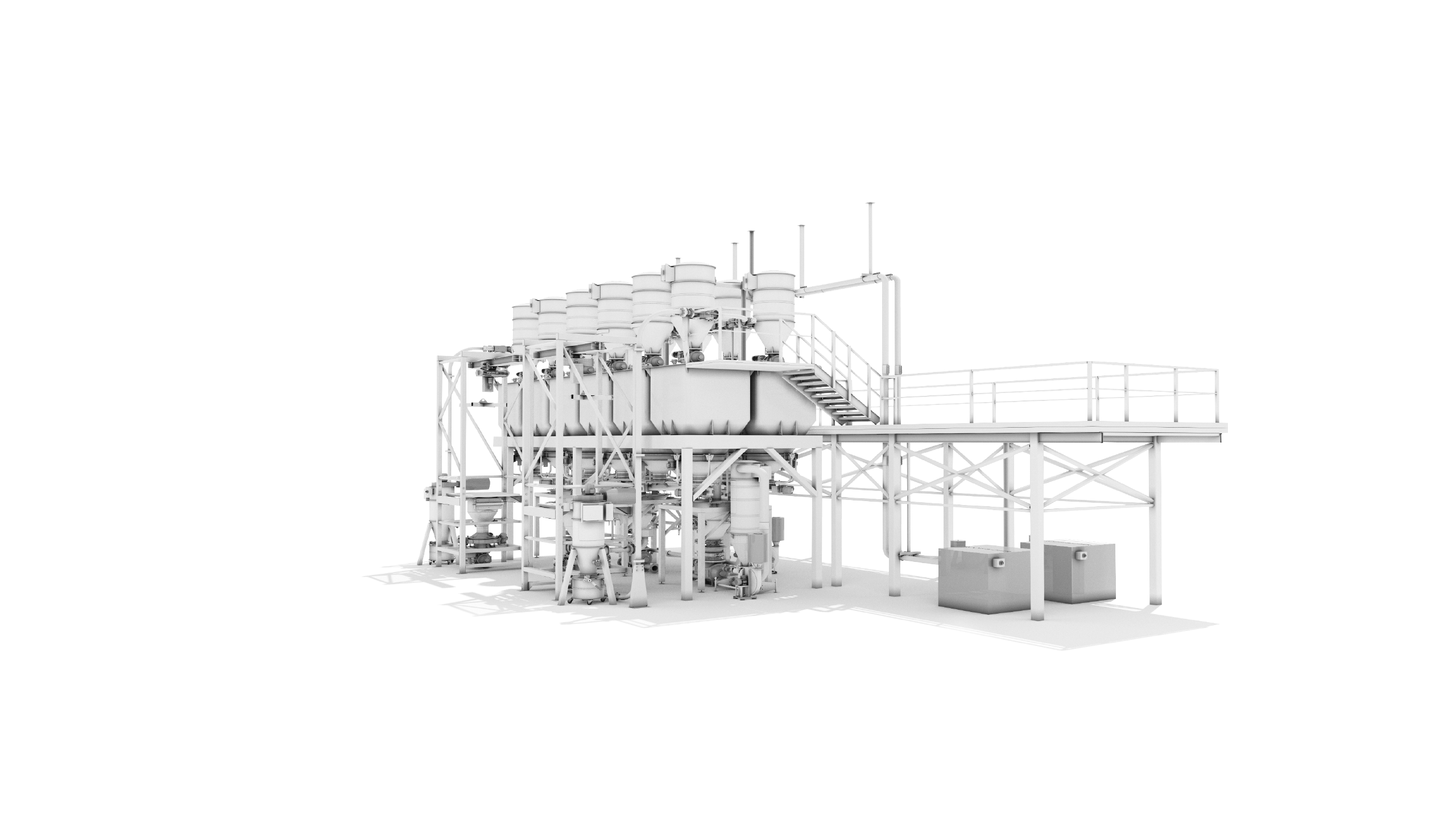

Overhead storage bins are filled with various feed ingredients. The system will call for feed recipes, which then draw from these bins and mix together. Completely smooth interior helps reduce feed hang-up.

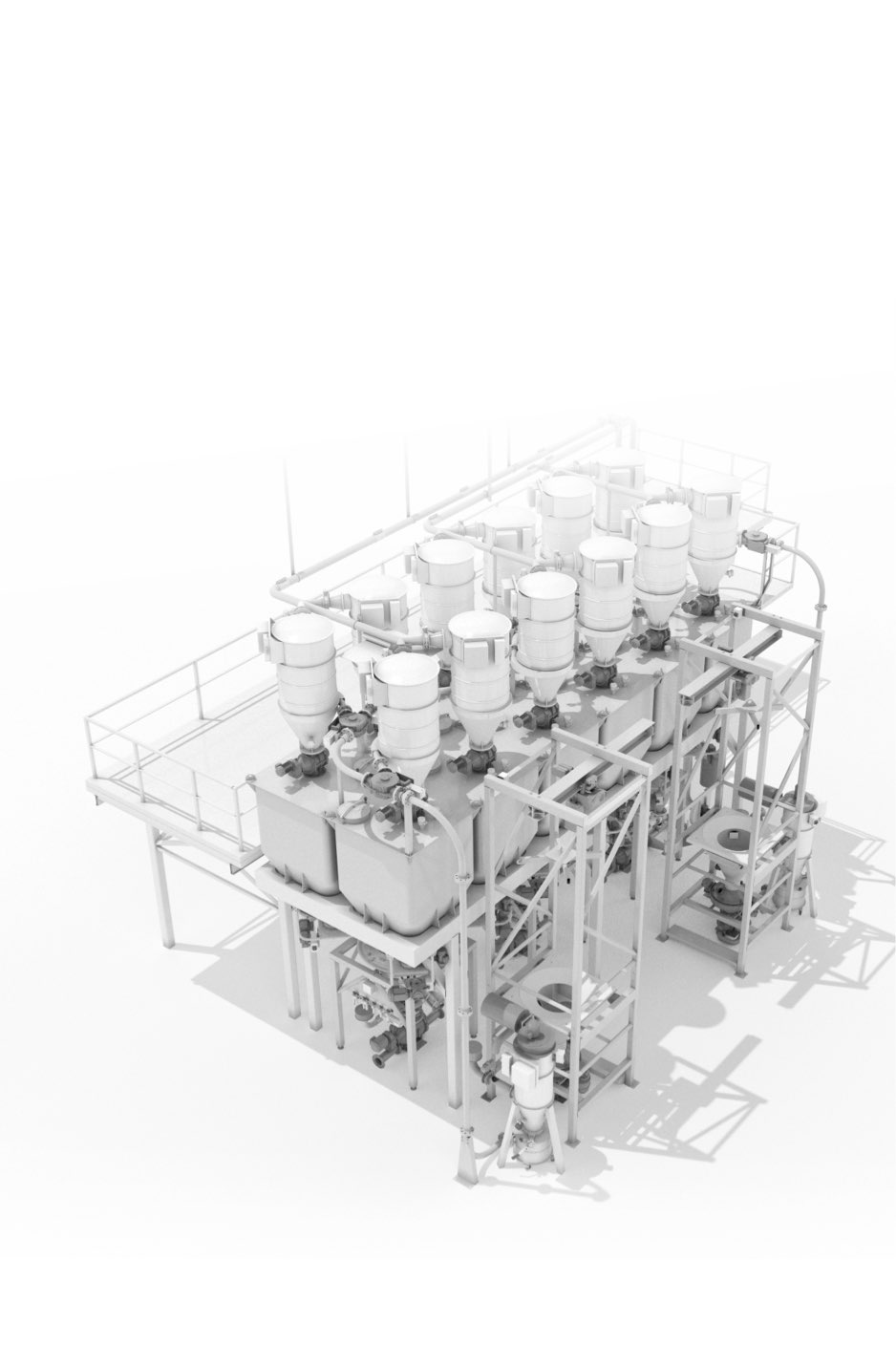

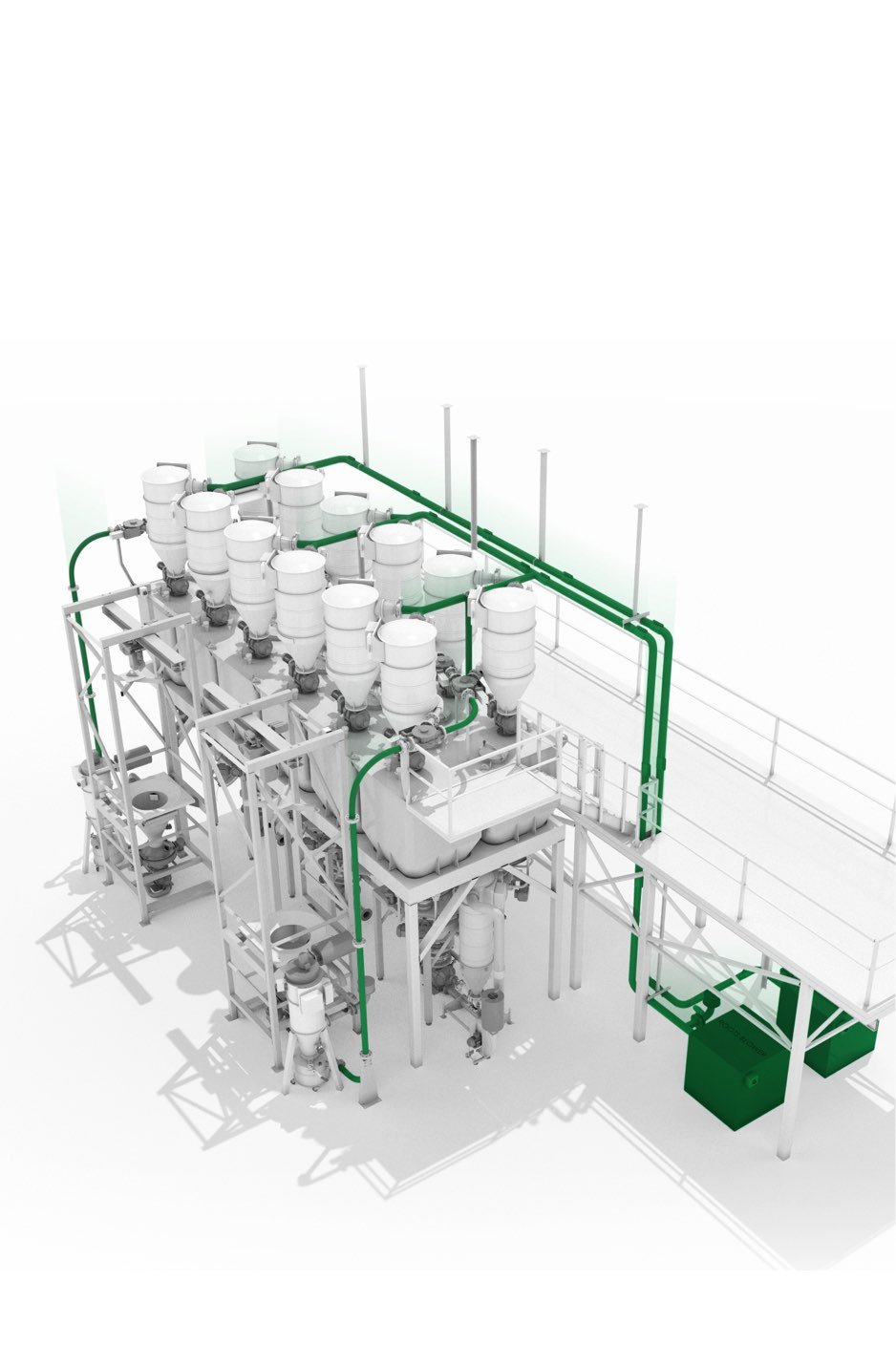

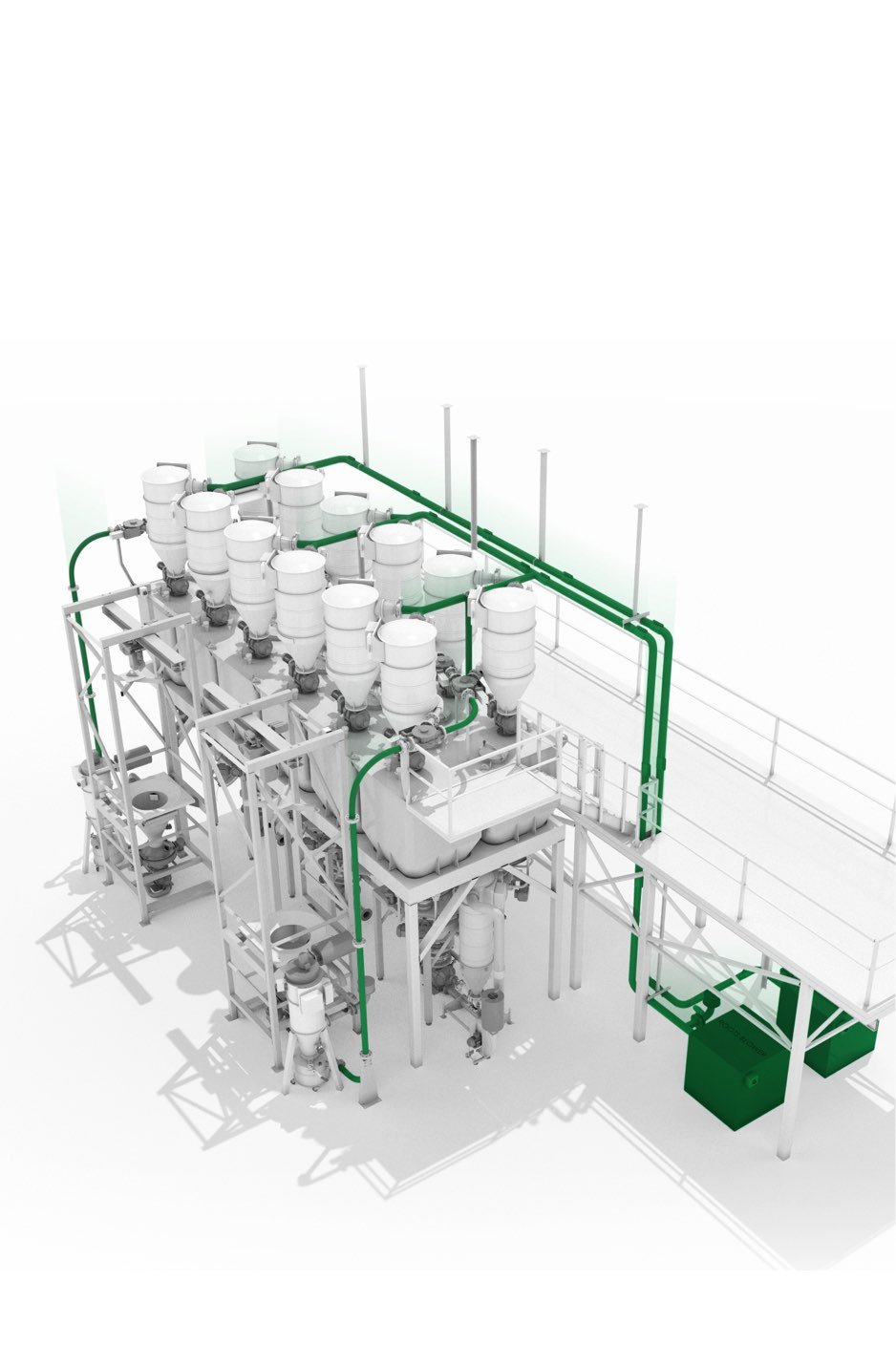

Custom, full-system food processing solutions and applied technology platforms designed, engineered, installed, and managed from start to finish.

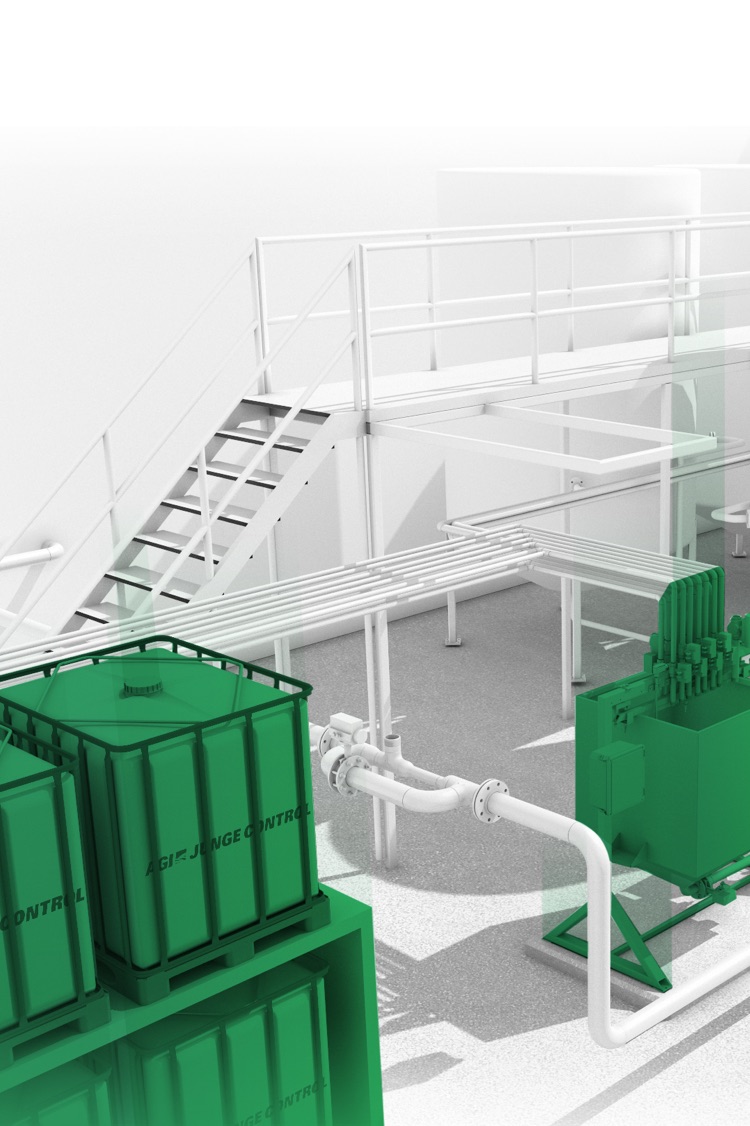

Pneumatic transfer (piping + blower) provides better airflow and even distribution, which helps for overall food safety.

Big Bag Unloading Stations are designed to unload big bags while adapting to requirements. Set at ground level for easy access.

Part of the Pneumatic Transfer technology, we design and manufacture high efficiency Cyclo-filters used for loading storage bins. Cyclo-filters are used to optimize transfer rate.

Bin Activators ensure constant flow of product.

Used to extract the exact amount of product required.

Provides higher accuracy for dosing of the product.

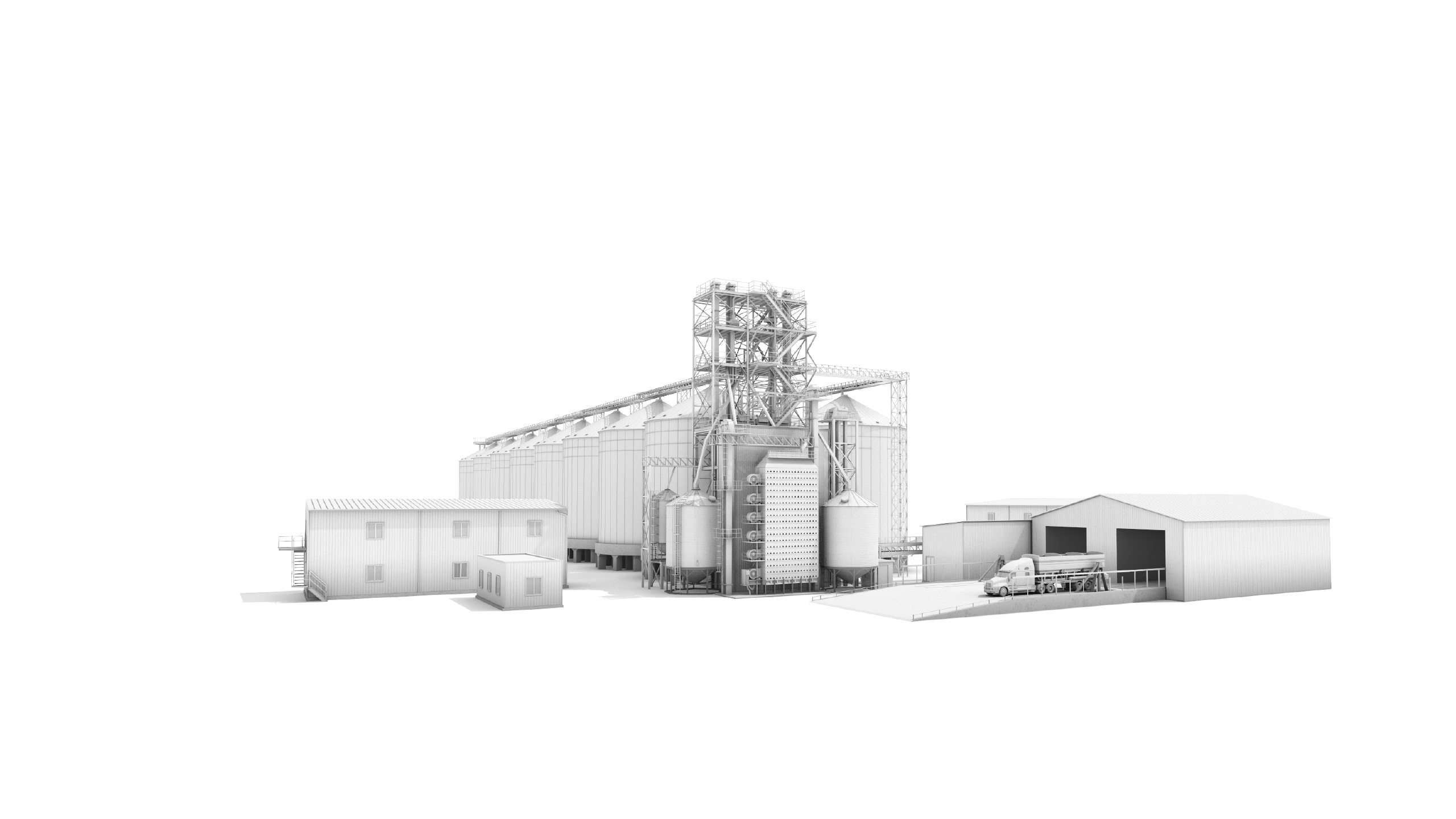

Farm and commercial solutions and systems for storage, handling, structures, processing, and controls in seed, fertilizer, grain, feed, and food. From planning and project management to engineering and manufacturing, partner with AGI, a global leader, supplying the world's food infrastructure.