Beta Series Color Sorter

Graphics Panel

- 15 “Linux based user friendly Graphic user interface (GUI) with Online Support System

- Self-diagnosis and auto memory of products with remote control setup

- Image capturing systems with 200 profiles storage that enables quick machine settings.

Features

- 16200 Pixels High speed Multichromatic Cameras

- Fast response Maglev ejectors with life of 10 Billion cycles

- Reverse Sorting & Size Sorting

- Optional 4 time sorting for better carry-over ratio

- Sniper technology -Target Located rejection for better carry-over ratio

- Higher Capacity – Strong Software algorithm to analyse the sorting materials

- Spectrum Confocal 2.0 for rejecting transparent plastic

- Simplified UI system with more user friendly HMI

Multi Chrome Cameras

- Multichromatic 16200 Pixel High Speed cameras with excellent scanning rate.

- Double Vision Scanning System to detect the slightest difference up to 0.01mm.

- Specially customized Spectrum Confocal 2.0 low distortion HD lenses to Identify pinpoint, Glass, plastic, desiccant images.

- Equipped for Reverse sorting & Size Sorting Methodology.

Technology

- 7th Generation FPGA Processing with Auto Intelligent Digital Image Sorting Technology.

- Product scanning speed of 35000 lines/sec.

- Auto calibration feature with Auto setting & Auto sorting control.

- High Brightness Adjustable Cool white LED Lighting systems with life span of 50,000 Hrs.

- Self – diagnosis and memorization of different scanned products.

Maglev Ejectors

- Maglev technology Ejectors with fast response time of 0.8 milliseconds, 3.8 mm Nozzle and a life time of 10 Billion Cycles.

- Upgraded with Quality ejector Feedback system that can monitor the ejections.

Chutes

- Anodized chutes having smooth surface to facilitate the even flow of the material.

- Heating provision for chutes to avoid choking of material.

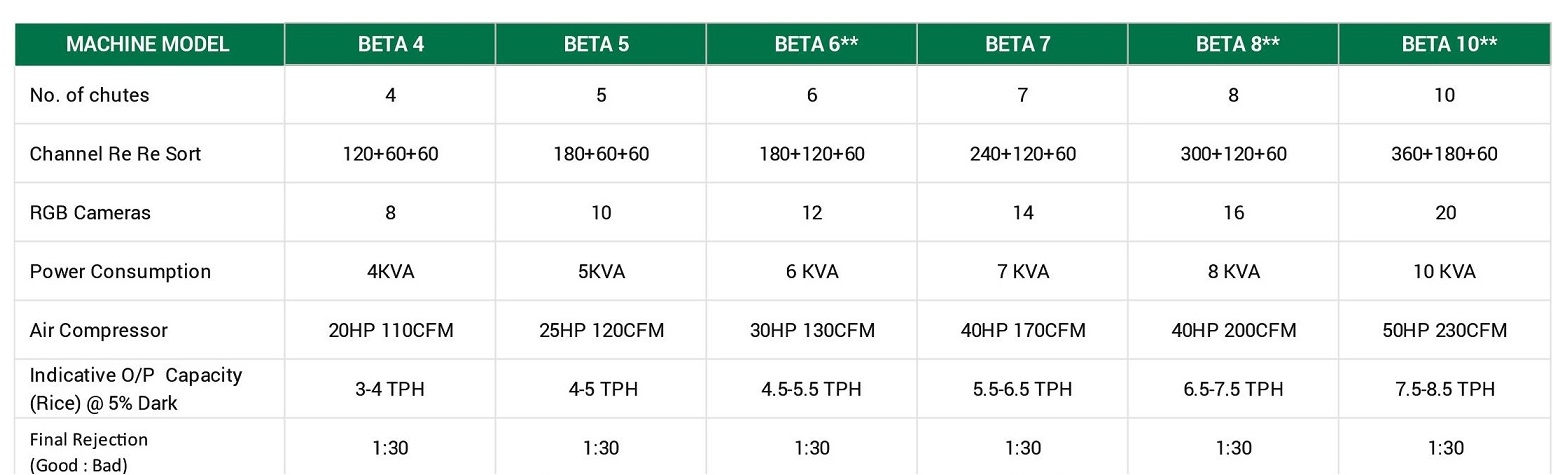

Technical Description

**Capacity & Rejection Ratio for other than Non Rice Grains may also vary wrt to Grain Size, Density & input impurity

For Immediate Assistance, contact the following:

-

North Africa Sales Office

Emanuele Dal Pozzo

P: +393456954496

E: emanuele.dalpozzo@aggrowth.com -

East Africa Sales Office

Willie Coetzee

P:+27 71 633 5365

E: willie.coetzee@aggrowth.com -

West Africa Sales Office

Vincent Joseph

P:+234 807 949 1118

E: vincent.mathews@aggrowth.com -

South Africa Sales Office

Willie Coetzee

P:+27 71 633 5365

E: willie.coetzee@aggrowth.comDwight Botha

P: +27 74 700 2738

E: dwight.botha@aggrowth.com -

EMEA Head Office

P: +39 051 798 107

F: +39 051 796 300

E: emea@aggrowth.com