The concept of this machine is designed with our many years of experience in grain processing field. This unique design is versatile and can handle all variety of finished/semi-finished product.

Controller automatically set the machine for desired Blending value & accordingly weighing bin measure the product with the help of load cell. If set value is achieved, weighing bin open and the product is discharged into the ribbon mixer. Our efficient ribbon mixer mixes the product till complete homogeneity is achieved. Once mixing is complete, the bagging attachment allows to bag the product to required weighment.

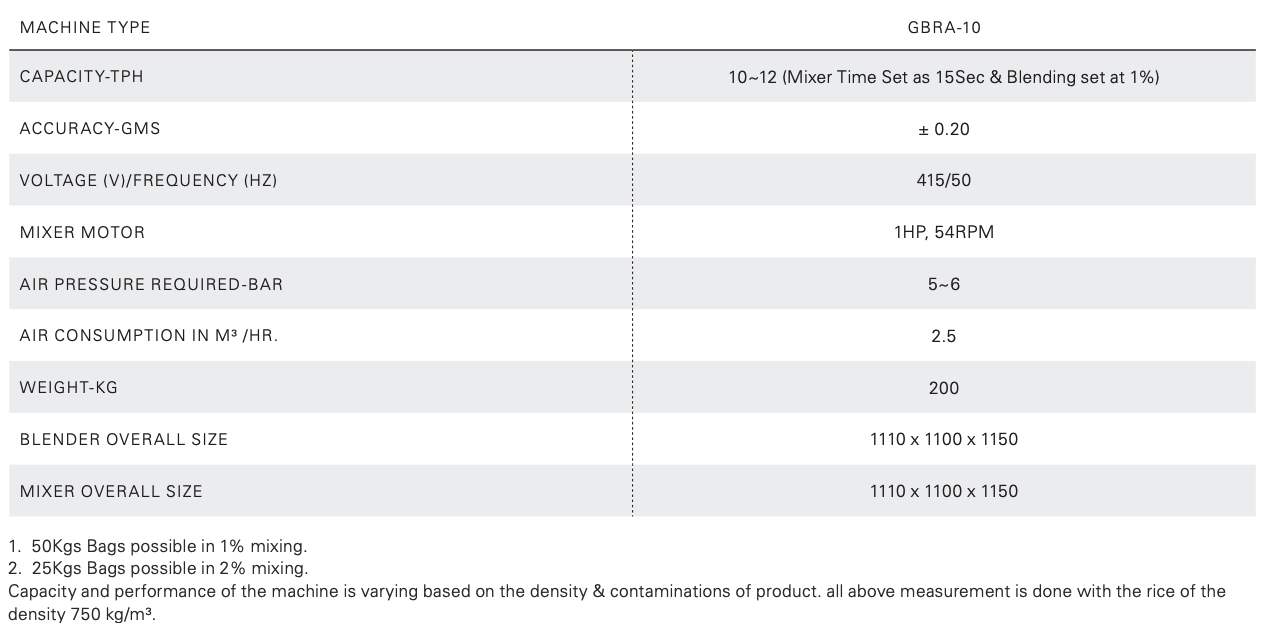

Capacity and performance of the machine will vary based on the density & contaminations of product. All above measurement is done with the rice of the density 750 kg/m³.