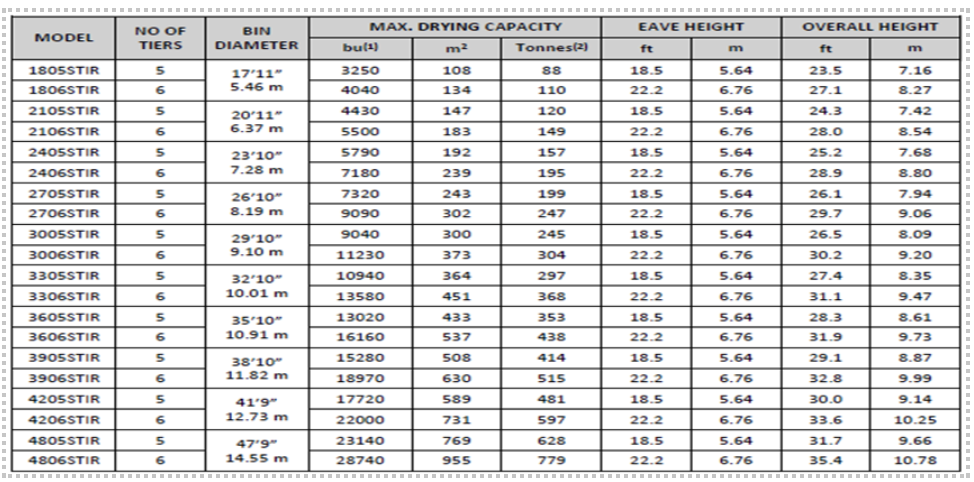

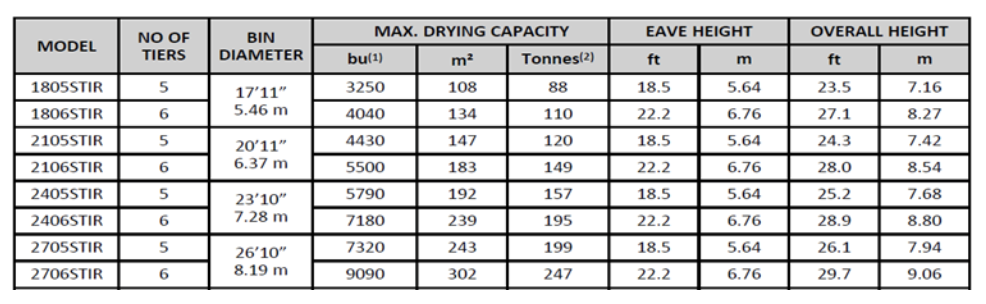

Made for hopper bins of 18' to 27', and flat bottom bins with diameters from 18' to 48' up to 6 tiers, our Stir bins are designed with heavier wall sheets than standard bins to provide extra support when the grain mixer is in motion.

How does it work? The grain mixer moves in a unique circular stirring pattern to ensure consistent and proper grain stirring. Down augers are spaced 4.5' apart and effectively pull drier grain about 2' around the augers from the bottom of the bin to the top. Augers will move approximately 2' in or out with each revolution around the bin, covering a larger area to increase productivity.

Stir bin kits come with eave shims that create a small gap between the roof panels and the sidewall top angle. This gap allows condensation that can collect on the underside of a stir bin roof to drip out of the bin and not back into the grain.

- Built-in DAPS (Down Auger Protection System)

- Main support beam with fill-hatch hanger brackets

- Rotating contactor with safety system

- Gear motor drive and circular track system with brackets

- Trolleys for the stirring augers

- 1.5 HP motor standard on single phase systems,

- 2 HP motors optional

- 2.65 HP motor standard on 230 volt and 460 volt 3-phase systems (special order)

- CSA-certified with single phase motors

- Moisture resistant electrical junction boxes

Down Augers

Down augers are spaced 4.5’ apart and will pull or mix grain from 2' on either side of the augers and move approximately 2’ in or out with each revolution around the bin

- The outside auger moves to within 12" of the bin wall eliminating the need for fixed down augers on the outside of the bin

- Three-point suspension system distributes loads evenly on the bin’s peak ring

- Positive chain drive prevents the possibility of slipping and moves the auger trolleys in unison

- Rigid wide flange beam acts as the backbone of the Smartstir System; trolleys roll on long–life cast iron rollers machined to fit between the flanges of the beam

- All electrical connections and enclosures are moisture resistant to deal with extreme conditions encountered in drying bins

Options Available

- Grain spreaders. Improve grain drying and storage by gently and evenly distributing the grain throughout the bin.

- Bin liners. Reduce the risk of grain spoilage due to condensation buildup on the bin wall. Available in various heights and can be bolted directly to the horizontal wall seams.

Hopper Bins

Flat-Bottom Bins