Conveyors

Small to large processing applications with minimum product degradation.

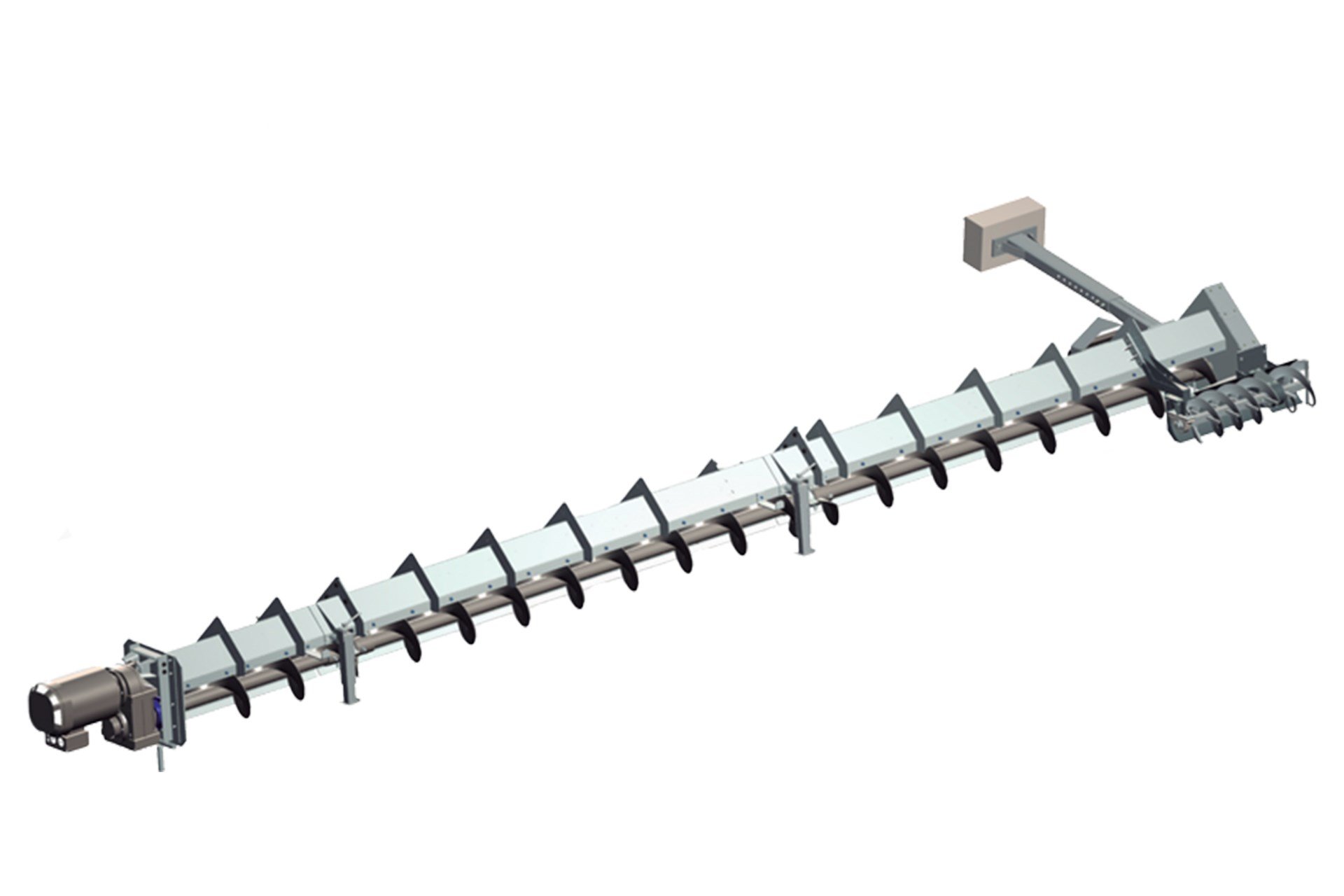

The AGI Helicoidal Screw Conveyor is used for continuous horizontal or diagonal one‐directional or reversible grain conveyance. The whole system is sealed to avoid any dust emissions and is made of galvanized steel to extend its lifespan.

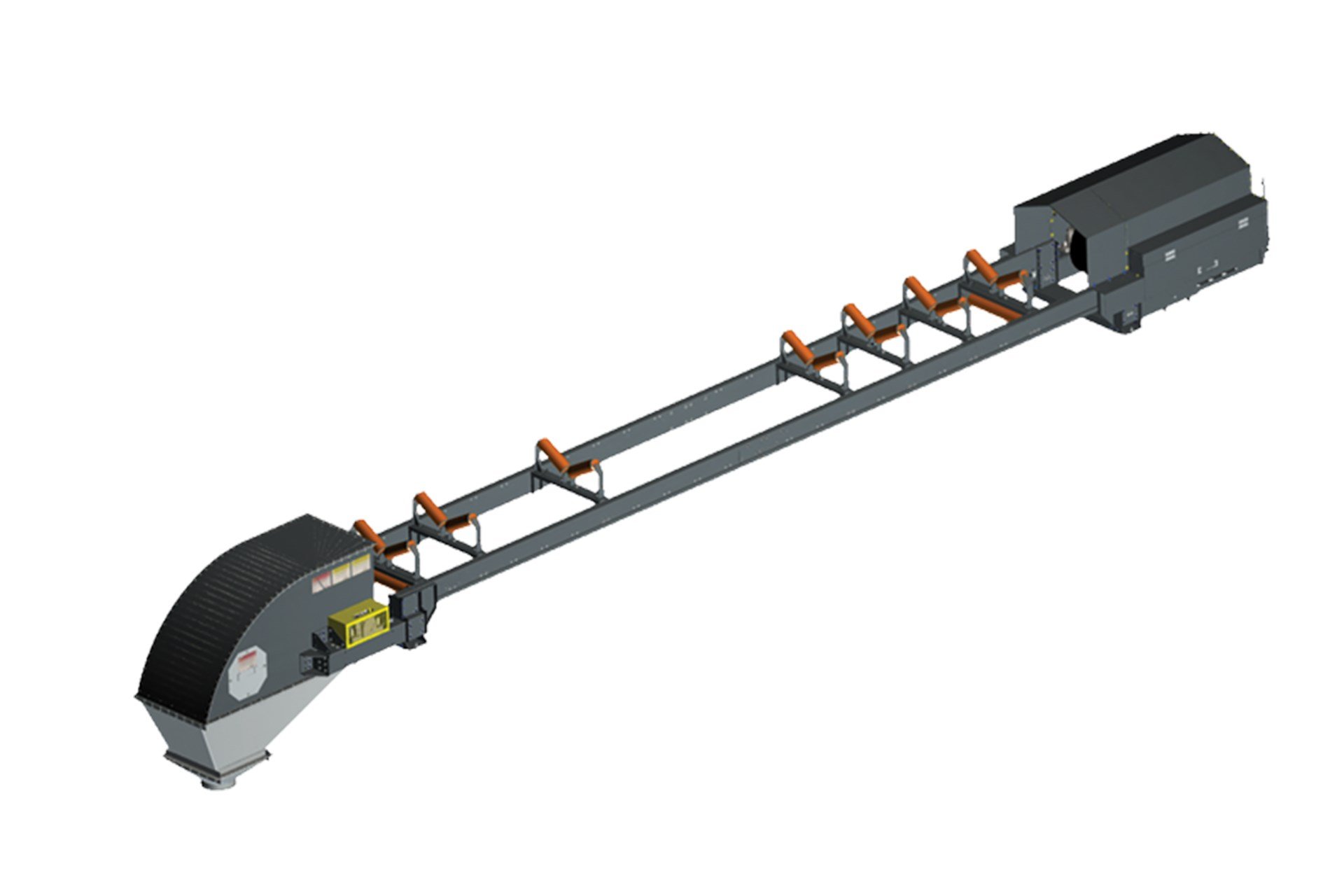

Designed for continuous horizontal or diagonal one‐way or reversible grain transportation, the AGI Open Belt Conveyor is constructed with a robust drive system and loading conveyor that can be fixed or mobile.

Designed for continuous horizontal or diagonal one‐way or reversible grain transportation, the AGI Conveyor Belt is constructed of galvanized steel and is sealed to prevent damp and dust.

The AGI Sweep Auger is designed to unload grain stored in the silo. It uses self‐lubricating plugs and protected bearings for added durability. Its modular design can be installed in a silo of any size.

Designed to work where loading angles are too steep for a standard belt conveyor, the Yargus Chain Paddle Conveyor loads efficiently, is environmentally sound, and is easy to service and maintain.

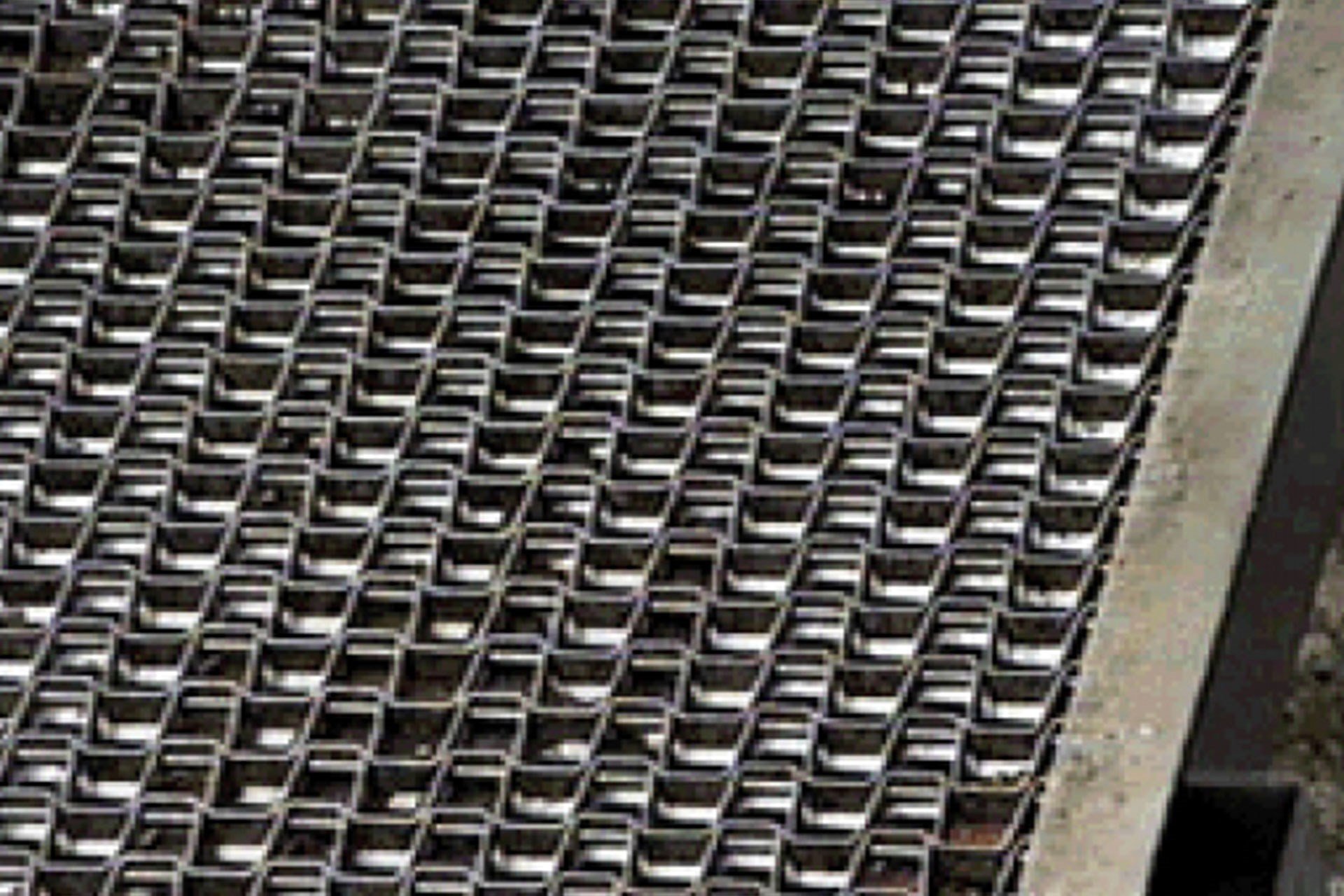

Layco's Flat Wire Chain Conveyor is available in 12", 18", and 24" widths. Units are designed to be portable or stationary and as blender loadout conveyors.

Suitable for under roof or on top of roof use, the Horizontal Chain Paddle is available in 90- to 400-tons-per-hour capacities.

Yargus' Shuttle Conveyor, at approximately half the size of a conventional conveyor, does the same amount of work at capacities from 60 to 1500 TPH.

The Tripper Conveyor is operated manually to discharge product to the left, right or the end and designed to load individual bins by moving over the top of bins on the Layco Stationary Conveyor.

Operating as a self-powered reversible conveyor, Yargus' Tripslinger travels the full length of the warehouse on the Layco Stationary Conveyor.

Hi Roller® model's unique bell-shaped carrying idler provides the trough for the belt and utilizes two externally isolated bearings.

Ideal for handling large capacities and continuous plant feed applications that run 24 hours a day, seven days a week. The Hi Life® idler is much thicker and bearings are much larger.

Configured with all the benefits of our industry leading Hi Roller® Conveyor, the Mini Roller® provides options for lower profile, lower capacity conveying. Perfect where space is limited.

An inexpensive, low capacity conveyor perfect where space is limited. The Lo Roller® utilizes flat idlers for belt load support and UHMW lined side slides for belt edge support.